- 812 -663-4196

- FAX: 812-663-4220

- 1954 North Montgomery Road Greensburg, IN 47240-1276

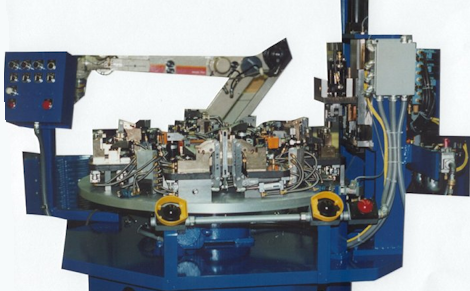

Features:

Hand Load fuel rail tube magazine

Feeder bowls orient and feed brackets, injector cups, regulator cups, diagnostic ports, service ports and end caps.

The following processes are fully automated while maintaining proper orientation of all components:

Feed tube to bend station

Bend tube to print dimensions

Transfer tubes from bend station to each subsequent station

Place and resistance weld brackets to tube

Drill multiple chip free holes in tube

Install fuel injector cups in tube

Install fuel regulator cup in tube

Install diagnostic port in tube

Install service port in tube

Install end cap on tube

Constant monitoring of components presence

Unload completed assemblies

Safety “see thru enclosure” of aluminum frame with 1 inch square black wire mesh, access doors and safety interlocks.